This stage depends on the printer and what they are wanting to print.

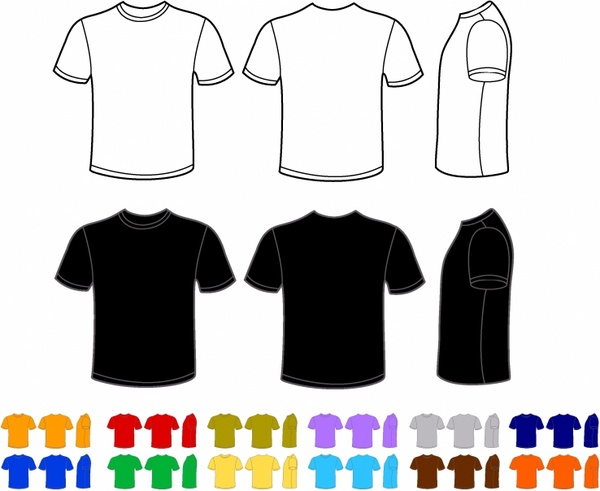

I did this while getting my graphic design degree and the insight was invaluable. If you are not having the shirts DTG printed and are on the route of screen printing you may be required to provide the artwork separated or some require each color on a layer with a master layer of how the design looks. If you’re new to the screenprinting process and don’t want to hassle your local screen printer with 1,000 questions, ask to do a few days of work experience. Screen printing is a method of printing on a screen. Learn about the printing options available to you. Determine why you require a shirt establish a budget for the purchase of a large number of shirts. However, not all printers worry about a base white when printing on a white garment, and you can specify your preferences in the specs. How do you design at shirt The 7-step process for designing a t-shirt. Don’t be surprised about this extra screen cost when you get a quote. Please note that most screenprinters prefer to do a white base screen for dark colored garments - it’s like an undercoat, on top of which they print the other colors. Also, by not printing the dark ink on dark garments, the design will work on navy, black or maroon colored T-shirts. If you include white ink, then this artwork has three colors – but I prefer not to print white ink on white T-shirts, or black ink on black T-shirts. Women typically have smaller chests and waists. Additionally, it is important to keep in mind the gender of the person wearing the shirt. If the design is too large, it may not fit on the shirt or look proportionate. If the design is too small, it may not be visible on the shirt.

This will save on screen setup costs in the long run. The design should be at least 12 inches wide and 12 inches tall. I always like to create my artwork so that it works on both dark and light-colored garments.

0 kommentar(er)

0 kommentar(er)